Risto Pasteurizers – Efficient, Reliable, and Energy-Saving Solutions for Milk Processing

Risto offers a range of high-performance pasteurizers designed to meet the needs of modern dairy processing. Our machines provide efficient, reliable, and energy-saving solutions, ensuring your milk is pasteurized safely and effectively. With advanced technology and user-friendly design, Risto pasteurizers help improve the quality of your milk while optimizing energy consumption. Explore our pasteurizer options to find the perfect fit for your business needs and take your dairy processing to the next level.

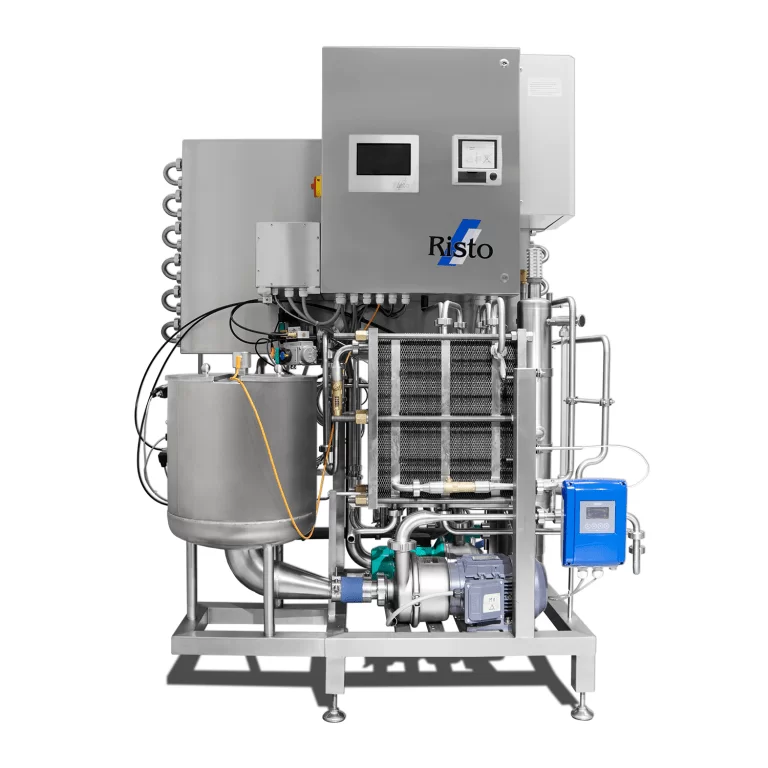

Milk pasteurizer – Risto Mini Milk Plate Pasteurizer PP-400

Starting from €29,900

Rent-to-own starting from €1,249 / month

Technical specifications

- Productivity: up to 4,800 liters per day

- Dimensions: L 120, W 80, H 180 cm

- Weight: 450 kg

- Electrical connection: 12 kW / 400 V 50 Hz

- Pipe connections:

- Product inlet DN15 with disc valve

- Product outlet DN15

- Ice water connection DN15 (if ice water is available)

- Hose connection option for cold-hot water 3/4”

- Compressed air DN10, 50 bar, 50 Nl/min (for safety valve)

About PP-400

- Gentle pasteurization

- Energy-efficient operation

- Up to 4,800 liters per day

- Quick installation

- Nearly fully automated operation

- Space-saving design

- Tailored to farmers‘ needs

- High quality

- Made in Germany

- Optimized, ergonomic, and streamlined workflow

- Very cost-effective operation

- Heat recovery

- Highly efficient and energy-saving operation

Exclusive benefits

Fully automated pasteurization and cleaning process

- Includes type testing by TUM Weihenstephan (conducted in-house by Risto)

- Operating time: 6 hours of continuous pasteurization before mandatory cleaning

- Automatic detergent dosing

- Detachable support track for control purposes (required by veterinary office)

- Insulated support track (lower heat loss)

- Includes certified line recorder and double-seat leak valve (Milk Regulation 627 in Germany)

- Product volume measurement with digital display

- Constant flow rate control to ensure product quality

- Optimized, ergonomic, and streamlined workflow

- Gentle product pump with electronic power limitation through frequency regulation

- Service and warranty from the German manufacturer (Risto)

- Made in Germany

With the Risto Mini Pasteur PP-400, you can handle the pasteurization of raw milk yourself. The pasteurizer is tested according to German standards and consists of several sections.

The regenerative section preheats the milk using swing water, while the heating section heats the milk to 74°C or up to 92°C. The average holding time is around 20 seconds.

Additionally, the pasteurization system features a regenerative cooling section that transfers cold from the incoming raw milk to the pasteurized milk, reducing energy consumption. Depending on your needs, the Risto Mini Pasteur PP-400 can be equipped with an additional cooling section for ice water cooling.

Furthermore, a centrifuge / homogenizer can be connected. The product inlet, outlet, and ice water connection have a nominal diameter of 15mm. The pasteurizer also includes connections for cold and hot water, as well as a compressed air connection (10mm).

With the Risto Mini Pasteur PP-400, you achieve gentle pasteurization with easy operation and low operating costs.

Additionally, we also offer batch pasteurizers.

| Product | Price Euro | |

| Plate Pasteuriser PP-400 | 29,99 | |

| Cleaning agent Niroklar und neomoscan 24 kg canister | includet | |

| Cleaning agent neomoscan 24 kg canister | includet | |

| Raw Milk Pump Unit | 4,99 | |

| Phone Service Hotline | includet |

Risto Milk Pasteur PP-600 / 1000

Starting from €39,900

Rent-to-own starting from €1,666 / month

Technical specifications

Dimensions: Length 240 cm, Width 90 cm, Height 220 cm

Weight: 650 kg – 750 kg

Pipe connections:- Product inlet DN25 with disc valve

- Product outlet DN25

- Ice water connection DN25

- Cold-hot water DN25

- Compressed air 1/2″ 8 bar, 125 Nl/min

About PP-600 / 1000

- Productivity: 600 to 1,000 liters per hour

- Gentle pasteurization

- Energy-efficient operation

- Quick installation

- Nearly fully automated operation

- Space-saving design tailored to farmers‘ needs

- High quality

- Made in Germany

- Optimized, ergonomic, and streamlined workflow

- Very cost-effective operation

- Heat recovery

- Highly efficient and energy-saving operation

Exclusive benefits

- Fully automated pasteurization and cleaning process

- Includes type testing by TUM Weihenstephan (conducted in-house by Risto)

- Operating time: 6 hours of continuous pasteurization before mandatory cleaning

- Productivity: 600 to 1,000 liters per hour

- Automatic detergent dosing

- Detachable support track for control purposes (required by veterinary authorities)

- Insulated support track (reduces heat loss)

- Includes certified line recorder and double-seat leak valve (compliant with Milk Regulation 627 in Germany)

- Product volume measurement with digital display

- Constant flow rate control to ensure product quality

- Optimized, ergonomic, and streamlined workflow

- Gentle product pump with electronic power limitation via frequency regulation

- Service and warranty from the German manufacturer (Risto)

- Made in Germany

With the Risto Milk Pasteur PP-600 / 1000, you can handle the pasteurization process yourself. Designed for simple and cost-effective heat treatment of raw milk, the system is equipped with high-quality technology.

The Risto plate pasteurizer features a stainless steel hot water pump, a plate heat exchanger, and an electric boiler. Additionally, the practical short-time pasteurizer includes an integrated pre-run tank.

The electronics of the milk pasteurizer include a switching device and a temperature recorder for reliable documentation of all measurement data. The regulation and control of the pasteurizer is managed via software, which also includes an inductive milk volume measurement system.

Furthermore, the Risto Milk Pasteur PP-600 / 1000 features a digital temperature controller. The milk circulation through the plate system and milk extraction from the pre-run tank are handled by stainless steel product pumps.

For effective heat retention, the pasteurizer is equipped with:

- A regenerative section

- A heating section

- A holding section

- A regenerative cooling section

- A final cooling section

Depending on the model, this pasteurizer can process between 600 and 1,000 liters of milk per hour.

| Product | Price Euro |

| Plate Pasteuriser PP-600 | 39,99 |

| Plate Pasteuriser PP-1000 | 43,99 |

| Cleaning agent Niroklar und Neomoscan 24kg canister | includet |

| Cleaning agent Neomoscan 24kg canister | includet |

| Raw Milk Pump Unit | 4,99 |

| Phone Service Hotline | includet |

Milk pasteurisers ZIP / cleaning plants / stack cleaners

Technical specifications of stack cleaning system

Dimensions:

- Length: 125 cm

- Width: 90 cm

- Height: 190 cm

Heating:

- 2 x 7.5 kW electric heaters

Advantages

Stack cleaning system made of stainless steel with direct connection to the pasteurizer, fully automated operation, consisting of 2 containers, with alkali and acid containers insulated, and equipped with:

- 2 x 7.5kW electric heaters with thermostat

- Various valves

- Concentration indicator

- Automatic detergent dosing system

In two separate containers, alkali and acid are reliably isolated from each other. The principle behind this system is circulation cleaning, meaning the cleaning solution is not discarded but captured for reuse. The captured cleaning solution is then used for the next rinse cycle in the Risto stack cleaning system.

Key features include:

- Electric heating with integrated thermostat

- Various valves

- Indicator for the concentration of each cleaner

- Connection pipes that direct the cleaning liquids from the Risto stack cleaning system to the subsequent pasteurizer

The cost for the cleaning technology is generally affordable, making it accessible for even small farms and dairy producers with a manageable budget. Additionally, the follow-up costs for water consumption are low due to the possibility of reusing rinse water – even for small production quantities.