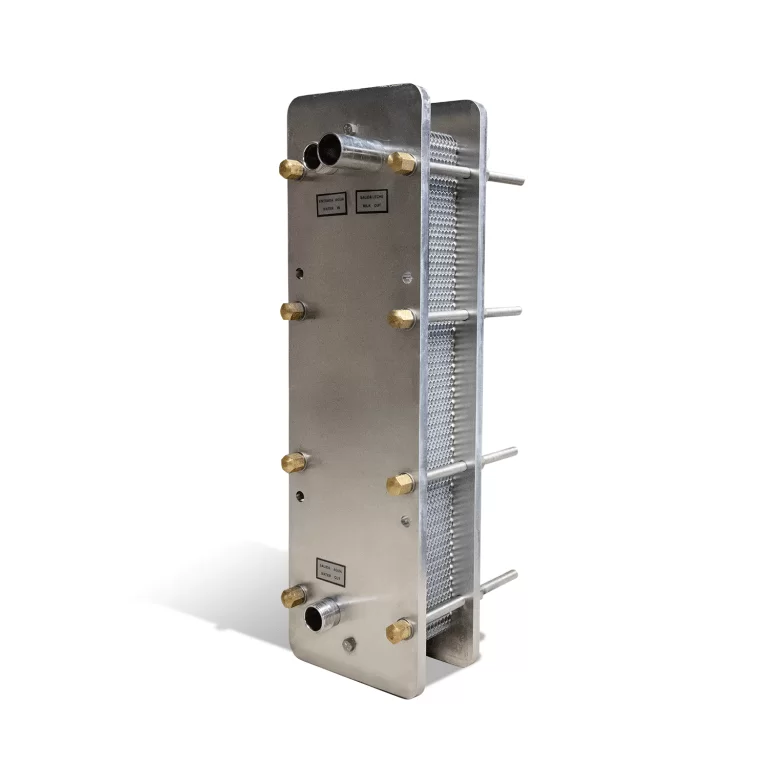

Plate Cooler (Plate Heat Exchanger, Heat Exchanger)

Pre-cooling ensures milk quality and reduces energy costs!

Starting from €3,750

Technical Data

- Number of Plates: 27 – 55

- Completely made of stainless steel

- Hygienic

Solid frame - Durable mounting bracket

- Suitable for up to 2 bar

- Plates easily replaceable without gluing

- Industry standard in the dairy sector for years

- Special plate design with high turbulence effect

- Plate design complies with USA 3A Sanitary Standard

- High cooling capacity due to efficient heat exchange

- Excellent plate cleaning properties

- Suitable for well water

- Water that is safe for livestock consumption can be used

- Water inlet/outlet: 1″ thread

- Milk inlet/outlet: 34 mm outer diameter (smooth pipe)

Why Rapid Cooling?

Rapid cooling with the plate heat exchanger ensures milk quality by quickly reaching the optimal storage temperature. This slows down bacterial growth in the milk, preserving its freshness and hygiene.

Pre-cooling milk with a plate heat exchanger before it enters the cooling tank is also cost-effective, reducing the energy consumption of the refrigeration unit. The heat exchanger operates with well water or tap water as the cooling medium.

The efficiency of pre-cooling in the plate heat exchanger depends on the water-to-milk flow ratio. Optimal pre-cooling is achieved with a ratio of approximately 2:1 (water to milk) in plate coolers.

Save Energy

Pre-cooling milk with the plate heat exchanger saves energy during subsequent cooling in the milk tank, as the milk enters the tank at a lower temperature. With a properly sized Risto plate cooler, you can reduce milk cooling energy costs by up to 60%.

Risto offers plate coolers in six different sizes, ensuring the optimal solution for every farm. Depending on your investment, you can choose a highly efficient model with 55 plates and a stainless steel frame for maximum cooling efficiency.

Freshly milked milk is immediately exposed to bacterial contamination from the moment of milking. The Risto plate cooler (plate heat exchanger, heat exchanger) rapidly cools it down, significantly inhibiting bacterial growth.

Beyond the hygienic benefits, pre-cooling also reduces energy costs. As the milk enters the cooling tank, it is already cooled to 14–20°C (depending on the water temperature). The available tap water or well water on the farm serves as the cooling medium. The manufacturer recommends a water-to-milk ratio of 2:1.

Milk and cooling water will never mix in the Risto plate cooler (plate heat exchanger, heat exchanger) due to the high-quality seals between the components. The stainless steel construction ensures a long service life, and the cooler can withstand pressures of up to two bar. Additionally, the plates can be easily upgraded or replaced with spare parts.

A significant cost-saving factor is the ability to use any well water for pre-cooling—water that is also safe for livestock to drink.

Price List

| Number of Plates | Milk Flow Rate (L/h) | Water Flow Rate (L/h) | Price Euro |

| 27 | 1650 | 4.850 | 1 |

| 31 | 1900 | 5.450 | 1 |

| 37 | 2350 | 5850 | 2 |

| 43 | 2750 | 6450 | 2 |

| 49 | 3250 | 6950 | 2 |

| 55 | 3650 | 7250 | 2 |

All prices excluding VAT.